Production de 1 à

1 million de pièces

La plateforme x3D-Print vous offre les meilleures ressources pour fabriquer vos pièces à partir de vos fichiers 3D

Prototypage Rapide

Production en Petites & Moyennes séries

Fabrication de pièces fonctionnelles

Réalisation de pièces esthétiques

Une fabrication décentralisée & certifiée ISO

Des pièces 100% conformes à votre cahier des charges.

Zéro Surprise !

Impression 3D

Accédez aux moyens industriels d’impression 3D plastique (SLA, SLS et MJF) et métalliques (SLM/DMLS), de petits et grands formats.

Coulée sous vide

Excellente alternative entre l’impression 3D et l’injection plastique classique, elle délivre des pièces de qualité à des coûts unitaires compétitifs.

Finitions

Pour un meilleur effet visuel, vous avez accès à un large panel de finitions, du sablage jusqu’à la peinture vernie, voire la métallisation.

Matières

Accédez à une large gamme de plastiques, métaux et élastomères, adaptés à la fois au prototypage et à la production en série.

Sécurité

La confidentialité est automatiquement appliquée sur tous les fichiers reçus, qui sont ensuite cryptés avant d’être transmis à notre supply-chain.

Fabrication 4.0

x3D-Print révolutionne la fabrication numérique pour la production à la demande de pièces performantes et contrôlées.

Une fabrication décentralisée.

Et certifiée ISO.

Accédez à une supply-chain industrielle et soigneusement éprouvée. Couplée à une solution logistique de premier plan, vous profitez ainsi qu’une capacité de près de 300 machines et d’un contrôle qualité pointu.

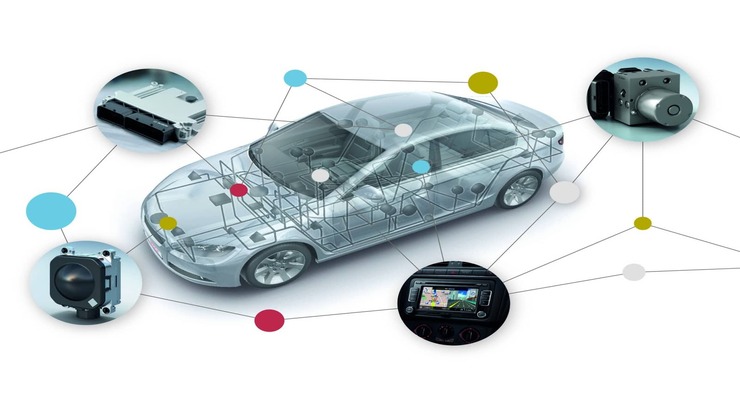

Industries

Grâce à sa plateforme disruptive, x3D-Print permet aux Grands Comptes de diverses industries (Energie, Transport, Services, etc) de réduire leur temps d’études de fabrication.

Du prototypage à la production en série, x3D-Print est un vrai logiciel de fabrication, et ce à partir de fichiers 3D de différents formats (neutres ou natifs).

La fabrication 4.0

La fabrication 4.0 est la quatrième révolution industrielle qui consiste à automatiser et numériser tous les processus jusqu’à la livraison des produits.

x3D-Print s’appuie sur ces avancées technologiques pour construire un réseau de production intelligent constitués de différents fabricants spécialisés capable de collaborer ensemble. Elle propose ainsi une capacité de production décentralisée, certifiée, réactive et innovante. De l’import d’un fichier 3D sur son interface, au chiffrage de la fabrication, jusqu’au contrôle qualité et la livraison, x3D-Print s’efforce de numériser et d’innover pour apporter à ses clients compétitivité et qualité.

Notre plateforme propriétaire de fabrication en ligne offre tous les outils utiles à la réalisation de prototypes fonctionnels ou esthétiques, et de pièces techniques finales, et tout cela très sécurisé. En effet, x3D-Print est la première plateforme proposant la sécurisation des fichiers 3D, ces derniers sont systématiquement cryptés avant la mise en production. Cette technique réduit ainsi le risque de fuites de données et garantit une meilleure protection des propriétés industrielle et intellectuelle de nos clients.

Avec notre bureau d’études, nous accompagnons nos clients industriels sur le long terme dans leurs développement produit, du prototype unitaire à la production en série de plusieurs milliers ou millions de pièces certifiées.

Côté production, pour le prototypage rapide ou la production en série, nous exploitons les technologies d’impression 3D industrielle telle que la stéréolithographie, le frittage laser de EOS et 3D Systems, le Multi Jet Fusion de HP et les technologies d’impression 3D métal SLM et DMLS.

Enfin, ces moyens sont complétés par une très large capacité de production par moulage, soit en coulée sous vide dans un moule silicone, soit en injection plastique traditionnelle.

Ils nous font confiance

PRÊT À COMMENCER VOTRE FABRICATION ?

Plus de 3500 d’entre vous utilisent x3D-Print